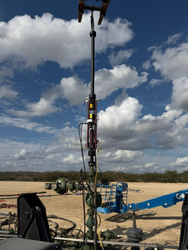

A Safety Milestone at the Wellhead

The First Fully Automated BPV Installed Remotely Outside the Red Zone

In November 2025, a significant safety milestone was achieved in South Texas when a producing well experienced an uncontrolled gas release, blowing to atmosphere, from the lower master valve. Instead of placing personnel near a live, blowing well, the operation resulted in the first fully automated Back Pressure Valve (BPV) installation performed remotely, with all personnel positioned outside the red zone. The job was executed by 3rd Degree Specialty Tools LLC as the service company, utilizing automated intervention technology built and patented by Heshka Oil LLC.

Why This Was Different

Traditionally, installing a BPV, whether during routine operations or an escalating event, means putting people close to live pressure. This job proved that approach is no longer necessary. Using a fully automated, pressure-balanced hydraulic wellhead lubricator with rotational capability, the BPV was installed, tested, and retrieved remotely, while all personnel remained clear of the red zone.

This Is Not Just a "Well Control" Tool

The most important takeaway from this operation is not that it worked on a blowing well. It's that this technology should be used whether a well control issue exists or not. There is no justification for placing people in the red zone anymore.

A New Safety Baseline

- Zero personnel exposure to live well pressure

- Fully remote, automated BPV installation and retrieval

- Mechanical isolation and pressure testing completed safely

- Reduced risk, reduced NPT, improved execution

This operation demonstrated a repeatable, scalable safety methodology that should be considered the default approach, not the exception.

The Bigger Picture

This isn't about reacting to emergencies. It's about changing how the job is done, every time. Automation doesn't replace experience. It removes exposure while experienced teams stay in control. That's how safety standards actually move forward.

Posted On:

2nd Feb 2026